Introduction

HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) are both forms of polyethylene plastic, which is one of the most commonly used materials in the world. These two types of polyethylene are distinguished by their differing molecular structures, which give them unique physical properties and make them suitable for specific applications.

HDPE has a more tightly packed molecular structure, leading to higher density, strength, and rigidity. It has a higher melting point and is often used in more durable and heavy-duty applications.LDPE, on the other hand, has a more branched molecular structure, making it less dense and more flexible. It has a lower melting point and is often used in applications requiring flexibility, such as plastic bags and squeezable bottles.

In the context of pharmaceutical packaging, both HDPE and LDPE are utilized but for different reasons, owing to their distinct properties. The choice between HDPE and LDPE can significantly affect the efficacy, safety, and shelf-life of pharmaceutical products.

Importance of choosing the right type of plastic in pharmaceutical packaging.

Choosing the right type of plastic for pharmaceutical packaging is a critical decision that has far-reaching implications for both manufacturers and consumers. The packaging material needs to meet stringent criteria to ensure it effectively protects the contents, maintains product integrity, and complies with regulatory standards. Below are some reasons why making the correct choice is crucial:

Product Safety

The packaging must not react with the pharmaceutical product it contains, thereby preventing contamination. Inappropriate material could lead to chemical reactions that compromise the safety and efficacy of the medication.

Shelf-Life

Different plastics offer varying levels of protection against external factors like moisture, light, and oxygen, all of which can affect the stability and shelf-life of a pharmaceutical product.

Usability

Ease of use is another factor to consider. For example, squeezable LDPE bottles are often used for eye drops, while rigid HDPE bottles are generally better for storing pills. The user experience, including opening, dispensing, and resealing the package, can be significantly impacted by the material choice.

Regulatory Compliance

Different countries have specific regulations for pharmaceutical packaging materials. The selected material must meet these standards to ensure safety and to be legally sold in that market. Often, plastics like HDPE and LDPE are favored due to their track record of compliance with FDA and other international guidelines.

Environmental Impact

Sustainability is becoming an increasingly significant consideration. The environmental impact of the packaging material, from production to disposal, is now an important criterion in material selection.

Cost-Effectiveness

Finally, cost is always a concern. While it shouldn’t compromise quality or safety, the economic efficiency of using one type of plastic over another can influence the final decision, particularly for products produced at scale.

Given these factors, the choice between HDPE and LDPE for pharmaceutical packaging isn’t merely a matter of preference. It’s a complex decision that requires a comprehensive understanding of both materials’ properties, the specific needs of the pharmaceutical product, and the regulatory landscape.

What is HDPE?

Molecular Structure of HDPE

HDPE is made up of a linear polymer chain with few branching or side chains, leading to a closely packed structure. This linear structure allows the molecules to be closely aligned, giving it a higher density compared to other forms of polyethylene like LDPE. Typically, it’s produced using catalysts in processes like the Ziegler-Natta polymerization or through metallocene catalysis methods.

Physical Properties

Strength: HDPE has high tensile strength, making it resistant to breakage.

Rigidity: Due to its dense molecular structure, HDPE is more rigid, making it suitable for applications where structural integrity is important.

Higher Melting Point: HDPE has a melting point between 120 to 180°C (248 to 356°F), higher than that of LDPE, making it more suitable for applications that require thermal resistance.

Common Uses in Pharmaceutical Packaging

Bottles for Pills: HDPE is frequently used to make rigid, impact-resistant bottles for pills and capsules. Its low moisture permeability helps in keeping the medication dry and intact.

Liquid Medication Bottles: Because of its higher chemical resistance, HDPE bottles are often used for storing medications in liquid form, like syrups or suspensions, as they won’t react with the contents.

Closures and Caps: The rigidity and strength of HDPE make it an excellent material for caps and closures that require a tight seal for preserving medication efficacy

What is LDPE?

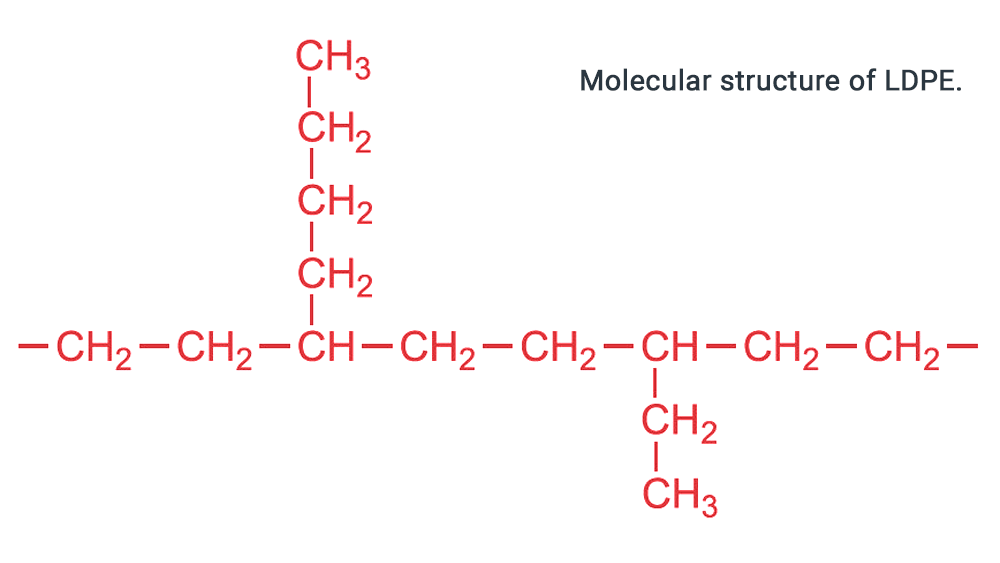

Molecular structure of LDPE

Low-Density Polyethylene (LDPE) is a type of polyethylene plastic characterized by its branched molecular structure. Unlike HDPE, which has a linear molecular arrangement, LDPE has a more ‘loose’ structure with numerous side branches. This branching prevents the chains from packing closely together, resulting in a less dense and more flexible material.

Physical Properties

Flexibility:One of the most prominent characteristics of LDPE is its flexibility. The branched molecular structure allows the material to be easily bent, twisted, and manipulated without breaking.

Lower Melting Point:LDPE has a lower melting point compared to HDPE, usually ranging between 105°C to 115°C. This makes it easier to process but also less suitable for applications where high temperature resistance is required.

Common Uses in Pharmaceutical Packaging

Squeezable Bottles:Due to its flexibility and lower melting point, LDPE is the go-to material for squeezable bottles commonly used for eye drops, ear drops, and some liquid medications. The material allows for easy dispensing of the medication with minimal effort.

Plastic Bags:LDPE is often used to make plastic bags for packaging pharmaceutical products. These could range from pouches for medical devices to bags that hold medication powders or tablets. The flexibility of LDPE makes these bags easy to open and close, offering both convenience and product protection.

Key Differences Between HDPE and LDPE

Understanding the differences between HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene) is crucial for selecting the right material for pharmaceutical packaging. Here, we break down these differences in terms of strength, flexibility, and chemical resistance, and discuss how these properties affect their suitability for various types of pharmaceutical packaging.

Strength

HDPE: Known for its rigidity and high tensile strength, HDPE is robust and can withstand higher levels of stress without deforming.

LDPE: Although durable, LDPE is generally not as strong as HDPE. It’s more susceptible to punctures and tears.

Flexibility

HDPE: Less flexible compared to LDPE due to its dense molecular structure, making it less suitable for packaging that needs to be easily squeezed or bent.

LDPE: Highly flexible and easy to seal, making it ideal for products that require squeezability, like eye drops or creams.

Chemical Resistance

HDPE: Highly chemically resistant, making it an excellent choice for storing more reactive substances. It is less permeable to gases, moisture, and odors.

LDPE: Although chemically stable, it generally offers less resistance to strong chemicals and higher permeability compared to HDPE.

Impact on Suitability for Different Types of Pharmaceutical Packaging

HDPE:

Strength: Due to its rigidity and strength, HDPE is commonly used in pharmaceutical containers that need to protect solid medications like tablets or capsules.

Chemical Resistance: Its high resistance to chemicals makes HDPE ideal for packaging that needs to hold reactive or volatile substances, including certain types of liquid medications.

LDPE:

Flexibility: LDPE’s flexibility makes it the material of choice for products that require easy squeezing, such as ointments or liquid solutions in dropper bottles.

Lower Chemical Resistance: While generally safe, LDPE might not be the best option for highly reactive substances. Careful consideration is required for its use in storing pharmaceuticals that may interact with the material.

Understanding these key differences will help you make an informed decision on which type of polyethylene—HDPE or LDPE—is most appropriate for your specific pharmaceutical packaging needs. Both materials have their advantages and disadvantages, and the right choice will depend on the particular requirements of the product being packaged.

Advantages of HDPE in Pharmaceutical Packaging

By offering chemical resistance, durability, and lower permeability to moisture and gases, HDPE becomes a compelling choice for pharmaceutical packaging. These attributes ensure that the medical product remains safe, effective, and of high quality throughout its intended shelf life, making HDPE a trusted choice for both manufacturers and consumers.

Superior Chemical Compatibility for Sensitive Pharmaceuticals

One of HDPE’s most notable features is its chemical resistance. It can safely contain a wide range of reactive substances, including acids, bases, and solvents, without degrading or leaching harmful substances into the product. This is crucial in pharmaceutical applications, where even a minor interaction between the packaging and the product can have significant repercussions for safety and efficacy. With its chemical resistance, HDPE minimizes risks related to chemical incompatibility, making it a preferred choice for storing sensitive or reactive pharmaceutical substances.

Unmatched Durability for Extended Product Life

HDPE’s robust molecular structure provides remarkable strength and durability, making it less likely to break or crack upon impact. This robustness is especially useful for pharmaceutical products that require long-term storage, as it offers added protection against physical damage during shipping, handling, and storage. The result is an extended shelf-life for the pharmaceuticals, reducing waste and economic loss for both manufacturers and consumers. HDPE’s durability also means that the containers can be made with less material without compromising on strength, making it a more cost-effective option in many cases.

Excellent Barrier Properties for Product Integrity

An often-underestimated advantage of HDPE is its lower permeability to moisture, gases, and odors. In pharmaceutical applications, this is invaluable as exposure to moisture can cause many medications to degrade or lose potency. Additionally, gases like oxygen can also react with certain pharmaceuticals, affecting their stability and efficacy. HDPE provides an excellent barrier to these external factors, preserving the quality and integrity of the medicinal products for longer periods.

Advantages of HDPE in Pharmaceutical Packaging

By offering flexibility, cost-effectiveness, and ease of use, LDPE provides a range of advantages for specific types of pharmaceutical packaging. When these benefits align with the requirements of the product being packaged, LDPE can be an excellent material choice.

Flexibility for Easier Squeezing and Handling

LDPE’s flexible nature makes it an excellent choice for containers that need to be easily squeezed, such as eye dropper bottles or liquid medicine containers. This characteristic enhances the user experience by allowing for more straightforward dispensing of the product. Furthermore, the flexible nature of LDPE can help in reducing waste, as it is easier to squeeze out nearly all of the product from a flexible container.

Typically Lower Cost than HDPE

From a cost standpoint, LDPE is generally less expensive to produce than HDPE. This cost-effectiveness makes it a popular choice for pharmaceutical companies that aim to manage production costs while still meeting quality and safety standards. The lower cost can also contribute to making healthcare products more affordable for end consumers.

Regulatory Considerations

The Food and Drug Administration (FDA) in the United States, along with similar organizations globally, have specific guidelines regarding the types of materials that can be used in pharmaceutical packaging. These guidelines are designed to ensure that the packaging material is safe and effective for its intended use. Both HDPE and LDPE are generally recognized as safe for contact with food and pharmaceuticals, provided they meet certain conditions outlined in regulations such as the Code of Federal Regulations (CFR) in the U.S.

Internationally, standards like the European Pharmacopoeia (EP) and the International Organization for Standardization (ISO) also provide regulations that influence the selection of materials for pharmaceutical packaging. These standards often align closely with FDA regulations but can have additional requirements that must be met for global distribution.

Known Concerns and Limitations

Permeability: While HDPE has a lower permeability compared to LDPE, it still allows for some gas and moisture transmission. For extremely sensitive substances, other materials like glass may be more suitable.

Cost: Generally, HDPE is more expensive than LDPE, which can be a consideration for companies looking to control costs.

Recycling and Environmental Impact: Although recyclable, not all recycling programs accept HDPE, which might be a concern for companies aiming for sustainable packaging.

Chemical Resistance: LDPE is less chemically resistant than HDPE, which means it may not be suitable for packaging certain kinds of pharmaceuticals.

Mechanical Strength: LDPE has a lower tensile strength, which makes it less suitable for products that need to withstand physical stress during shipping or handling.

Temperature Sensitivity: LDPE has a lower melting point, making it less ideal for products that need to be sterilized at high temperatures.

Understanding these limitations and the regulatory landscape is essential for pharmaceutical companies to make an informed decision about whether to use HDPE or LDPE for their packaging needs. Both materials have their own sets of advantages and disadvantages, and choosing the right one can have a significant impact on the product’s efficacy, safety, and marketability.

Conclusion

Choosing the right type of plastic for pharmaceutical packaging is a complex yet crucial task. This choice not only impacts the safety and efficacy of the product but can also significantly affect its market acceptance and long-term success. Both HDPE and LDPE are widely used plastics, but due to their respective molecular structures and physical properties, they offer different advantages and limitations in the context of pharmaceutical packaging.

In terms of regulatory requirements, such as those set forth by the FDA and other international standards, both types of plastic are generally acceptable choices. However, they each come with their own sets of limitations and considerations. As a result, pharmaceutical companies need to carefully assess the specific needs of their product to determine which material is most suitable for their particular application.

Overall, a comprehensive understanding of HDPE and LDPE, including their applicability, strengths, and weaknesses in pharmaceutical packaging, as well as considerations related to regulations and cost, will aid in making more informed decisions. This will ensure that the product not only meets all applicable quality and safety standards but also fulfills the needs of both consumers and the pharmaceutical company itself.