Introduction

Plastic bottles are ubiquitous, from food and beverage packaging to detergents, and even in pharmaceuticals and healthcare products. Their advantages of portability, lightweight design, and cost-effectiveness make them the preferred packaging material for a wide range of products. Especially in the pharmaceutical and healthcare industries, plastic bottles not only contain the products but also serve multiple functions such as protecting the contents, extending shelf life, and facilitating portability and ease of use.

However, not all plastic bottles are the same or interchangeable. Different types of plastic bottles are composed of distinct plastic materials, each with its unique physical and chemical properties, which determine their suitability and environmental impact. For instance, some plastic bottles are better suited for storing alkaline or acidic substances, while others excel in specific applications due to their temperature resistance or barrier properties. Likewise, different plastic materials exhibit differences in terms of environmental durability and recyclability, a crucial consideration in today’s increasingly environmentally conscious society.

This article aims to explore the differences between two common types of plastic bottle materials – High-Density Polyethylene (HDPE) and Polyethylene Terephthalate (PET) – concerning their applications in pharmaceutical and healthcare product packaging. We will analyze and compare them from various perspectives, including their physical properties, chemical properties, environmental impacts, and practical applications. The goal is to provide industry professionals and the general consumers with valuable insights and guidance when choosing and using these two types of plastic bottles. By gaining a deep understanding of the characteristics and distinctions between these materials, we can make more informed decisions, whether considering product quality, user experience, or environmental sustainability.

What’s the Difference Between HDPE and PET?

High-Density Polyethylene (HDPE) and Polyethylene Terephthalate (PET) are two commonly used plastics, each with distinct characteristics. HDPE is known for its high strength-to-density ratio, making it ideal for robust containers that can withstand impact. It is often opaque and has a higher temperature resistance, suitable for products requiring long-term storage. PET, on the other hand, is transparent and excellent for showcasing the contents. It’s generally less heat-resistant than HDPE but has a better barrier against moisture and gases, making it a popular choice for food and beverage packaging. Both materials are recyclable, but their applications and environmental impacts vary due to these inherent differences.

Comparison of Physical Properties

| Property | HDPE | PET |

| Density | 0.94 – 0.97 g/cm3 | 1.3 – 1.4 g/cm3 |

| Gamma Radiation Resistance | Fair | Good |

| UV Light Resistance | Poor | Fair |

| Water Absorption 24 hours | 0.005%- 0.01% | 0.1%- 0.2% |

| HDT @0.46 Mpa (67 psi) | 60°C – 90°C | 75°C – 115°C |

| HDT @1.8 Mpa (264 psi) | 45°C – 60°C | 65°C – 80°C |

| Coefficient of Linear Thermal Expansion x 10-5 | 6 – 11°C | 6 – 8°C |

| Fire Resistance | 17 – 18 | 23 – 25 |

| Strength at Break (Tensile) | 25 – 45MPa | 45 – 70MPa |

Comparison of Chemical Properties

| Property | HDPE | PET |

| Glycerol @ 100%, 20°C | Satisfying | Satisfying |

| Sodium hydroxide @ 10%, 20°C | Satisfying | Satisfying |

| Sodium hydroxide @ 10%, 60°C | Satisfying | Non Satisfactory |

| Strong acids @ concentrated, 20°C | Satisfying | Non Satisfactory |

Appearance: PET is a clear plastic while HDPE is opaque.

Stress cracking: PET Plastic bottles and containers have better resistance. HDPE is highly prone to environmental stress cracking due to its semi-crystalline nature. With higher molecular weight, crystallinity decreases. Thus, the plastic becomes more resistant to environmental stress cracking. Additionally, bottle-grade PET is amorphous and is engineered to prevent crystallization. If it crystallizes, it will lose its transparency as well as show poor impact resistance.

Durable and temperature resistant: HDPE containers are slightly more durable and temperature resistant. They have a high operating temperature of 160°F compared to 145°F for PET bottles.

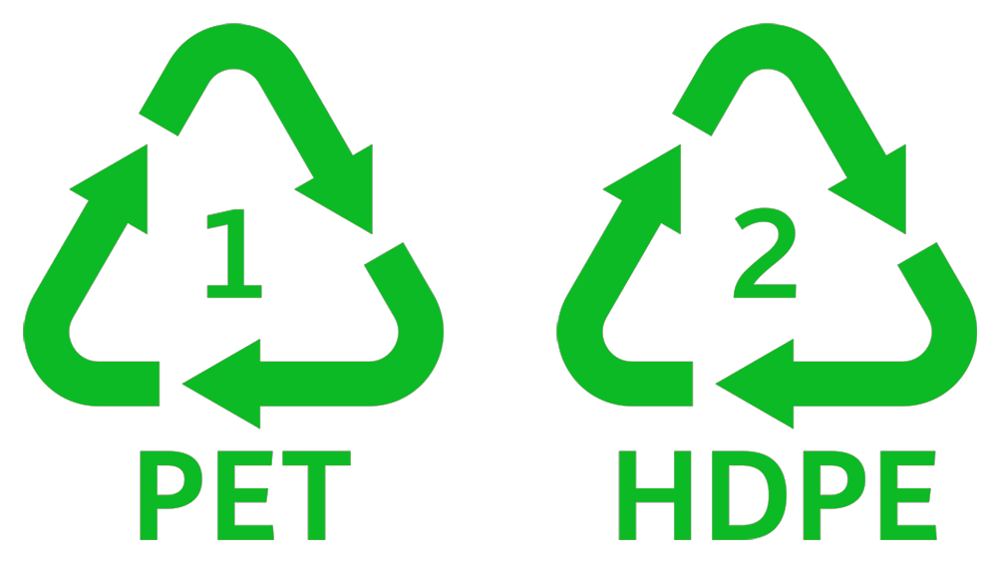

Sustainability and recyclability are becoming key aspects when it comes to material selection. Both HDPE (code – 2) and PET (code – 1) are recyclable. The low diffusion coefficient makes polyethylene terephthalate (PET) much more suitable as a recovered, recycled material. Hence, it continues to remain a sustainable choice for the food and beverage packaging industry.

Different Manufacturing Techniques:HDPE vs PET Bottles

HDPE Bottles

The production of HDPE bottles typically involves two methods: Extrusion Blow Molding (EBM) and Injection Blow Molding (IBM).

PET Bottles

To produce PET bottles, two main methods are typically used: single-stage injection stretch blow molding and two-stage injection stretch blow molding.

Recyclability

- Recycling Symbols: HDPE is typically labeled with “2,” while PET is labeled with “1.”

- Applications after Recycling: Recycled HDPE is commonly used in rigid plastic products, whereas PET is often used in textiles or reused in packaging.

- Recycling Methods: PET bottles can be recycled mechanically, and they may also undergo chemical recycling to return to raw materials, while HDPE is typically mechanically recycled.

HDPE or PET Plastic Bottle,Which one is More Suitable for Pharmaceutical Packaging?

The choice between HDPE (High-Density Polyethylene) and PET (Polyethylene Terephthalate) for pharmaceutical packaging is a complex decision that depends on several factors, such as the type of medication, shelf life, storage conditions, and environmental concerns. Here’s a breakdown of the considerations for each material:

HDPE Bottles in Pharmaceutical Packaging

Advantages:

Chemical Resistance: HDPE is known for its resistance to many chemicals, which makes it ideal for certain types of medications.

Temperature Resistance: HDPE can withstand higher temperatures, which is beneficial if the pharmaceuticals require sterilization.

Opaque: HDPE’s opacity can protect light-sensitive medications from deterioration.

Moisture Barrier: Provides good protection against moisture, especially important for hygroscopic substances.

Disadvantages:

Gas Permeability: HDPE is more permeable to gases like oxygen, which could be a concern for medications that are sensitive to oxidation.

Environmental Impact: While HDPE is recyclable, the rates of recycling are generally lower than that for PET.

PET Bottles in Pharmaceutical Packaging

Advantages:

Clarity: PET bottles are transparent, which allows for easy inspection of the medication.

Gas Barrier: PET has better barrier properties against gases, thus preserving the efficacy of the medication for a longer time.

Recyclability: PET is widely recycled and can be reprocessed more easily compared to HDPE.

Lightweight: PET bottles are generally lighter than HDPE bottles, which can reduce shipping costs.

Disadvantages:

Temperature Sensitivity: PET bottles are generally not as heat-resistant as HDPE, which might not make them suitable for medications that require high-temperature sterilization.

Cost: PET can be more expensive than HDPE, which could be a factor depending on the scale of production.

Final Verdict

For Light-Sensitive Medications: HDPE might be the preferred option due to its opacity.

For Oxygen-Sensitive Medications: PET might be more suitable due to its lower gas permeability.

For High-Temperature Sterilization: HDPE might be the better option.

For Environmental Concerns: PET’s higher recyclability may make it more suitable if this is a key consideration.

Ultimately, the choice between HDPE and PET for pharmaceutical packaging will depend on the specific requirements of the medication in question, cost considerations, and the manufacturer’s focus on sustainability.