Key Takeaways

- Proper storage of HDPE bottles minimizes risks like contamination and chemical degradation.

- Implement cost-effective solutions such as modular shelving and climate-controlled units.

- Support sustainability by reducing waste and promoting recycling.

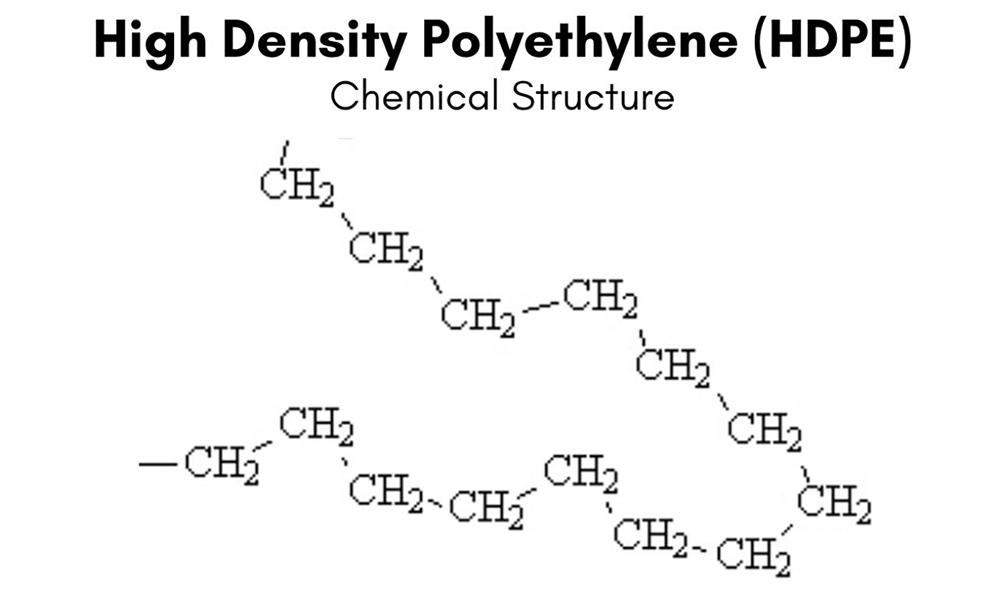

Understanding HDPE Bottles: Properties and Benefits

High-Density Polyethylene (HDPE) bottles are widely used in industries like pharmaceuticals due to their strength, durability, and resistance to chemicals. These bottles are lightweight and recyclable, making them an environmentally friendly choice. Learn more about HDPE tablet containers here

Best Practices for Storing HDPE Bottles

- Temperature Control: Store in a cool, dry place, avoiding direct sunlight.

- Vertical Orientation: Keep bottles upright to prevent leaks.

- Avoid Overpacking: Leave adequate space between bottles to prevent damage.

- Regular Inspections: Periodically check for signs of wear, discoloration, or cracks.

Common Risks Associated with Improper Storage

Improper storage can lead to several problems, including:

Chemical Degradation: Contents may become unstable when exposed to heat or UV light.

Contamination: Poor storage conditions can increase the risk of contamination.

Financial Loss: Damaged bottles or degraded contents lead to waste and increased costs.

Cost-Effective Storage Solutions for HDPE Bottles

Consider the following strategies to optimize storage:

Modular Shelving Systems: These save space and make bottles more accessible.

Climate-Controlled Units: Maintain consistent temperature and humidity levels to protect bottles.

For more information about our packaging solutions, visit LaiyangPackaging‘s Product List

Environmental Considerations in HDPE Bottle Storage

Proper storage supports sustainability efforts by reducing waste and extending product life. Additionally, HDPE bottles are recyclable, which aligns with global environmental goals. Learn about recycling initiatives from EPA’s Recycling Program.

Regulatory Compliance in Storing Pharmaceutical Packaging

For pharmaceutical packaging, adhering to Good Manufacturing Practices (GMP) is critical. Storage facilities should comply with regulations around temperature control and contamination prevention to maintain product integrity and meet legal requirements.

Real-World Case Studies: Successful Storage Strategies

Industry leaders have successfully implemented modular storage systems and climate-controlled environments to optimize their storage processes. These changes resulted in reduced costs, minimized risks, and increased operational efficiency. Explore similar solutions on our official website.

Frequently Asked Questions about HDPE Bottle Storage

What are the ideal storage conditions for HDPE bottles?

Store them in cool, dry environments, away from direct sunlight and extreme temperatures.

How long can HDPE bottles be stored without risk?

When stored under optimal conditions, HDPE bottles can last several years.

What are the signs that an HDPE bottle is no longer safe to use?

Discoloration, cracks, or leakage indicate that the bottle is no longer safe.

Can I store different substances in the same HDPE bottle?

Avoid mixing substances unless they are confirmed to be chemically compatible.

Conclusion

Storing HDPE bottles properly is essential to reduce risks, minimize expenses, and support sustainability. By following best practices and implementing cost-effective solutions, you can ensure your products remain safe and compliant. Visit LaiyangPackaging to explore our range of pharmaceutical packaging solutions. Contact us today to learn how we can meet your packaging needs!