When we open a bottle of newly purchased medicine, we will find that the bottleneck is always covered with a foil seal. Some are plastic, and some are aluminium foil. Well, do you know how they work and seal the bottle? This article will give you a detailed understanding of how to seal plastic medicine bottles.

At present, the most widely used sealing liners in the market are pressure-sensitive seals and induction heat seals. Pressure-sensitive seals are used for medicine in pill, tablet, capsule form etc. An induction heat seal liner is used for liquid medicine to prevent them from spilling out.

The reason that the seal liner was discovered goes back to the year 1982.

On September 29, 1982, in Chicago, United States. Mary Kellerman, the 12-year-old child, took Tylenol because of the cold. But, he was dead within a few hours after taking medicine. On the same day, another guy name Adam Janus took the same Tylenol capsule and died. Unfortunately, there were three people died after taking Tylenol in the following days. After investigation, people found the medicine that the dead people had taken contained cyanide. Someone put the cyanide into the Tylenol bottle. The pharmaceutical manufacturer urgently recalled 30 million bottles of Tylenol. After that incident, 270 other cases of pill tampering occurred in the Chicago area. The pill tampering could not be found because there was no foil on the bottle mouth at that time.

One year later, in 1989, the FDA established guidelines for tamper-proof drug packaging. With technology development, seal liners are rapidly used worldwide.

What is the difference between the Pressure sensitive liners and the Induction heat seal?

Pressure Sensitive Liners:

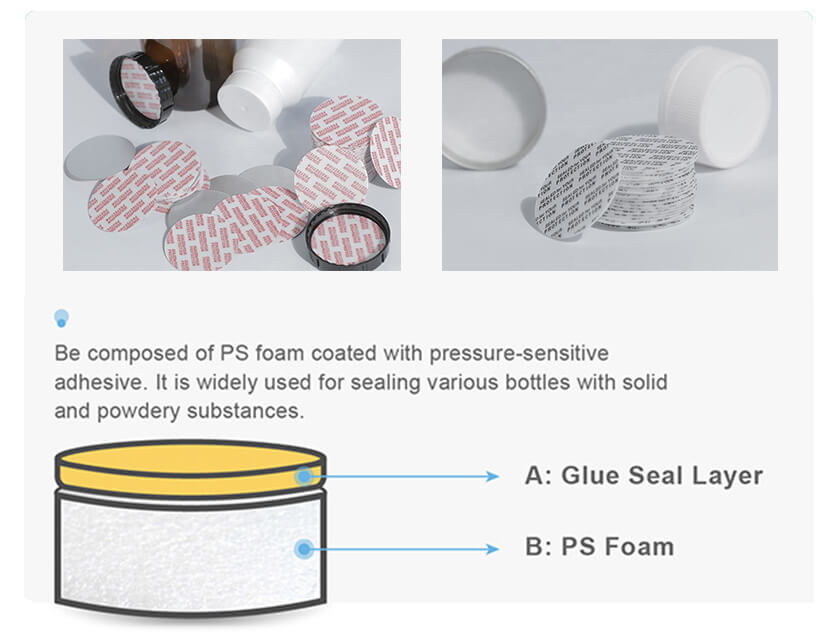

The material of Pressure sensitive liner is Polystyrene foam, which can be in direct contact with the medicine.

Pressure sensitive liner is a fast, easy way to seal the bottle with the tamper-evident feature. Its material, polystyrene foam, is a kind of safe material that can be in direct contact with the medicine.

The liners work for all containers made of glass and plastic. But because of their water permeability, they’re ideally used for solid medicine like capsules, pills, tablets etc.

How does the pressure-sensitive seal work to bottle?

Put the pressure-sensitive seal inside the cap (the side coated with a torque-activated adhesive is outside); screw the cap tightly, and then the liner will be sealed on the bottle mouth by the pressure.

Notices:

- It takes about 24 hours to have a better sealing performance. So please do not open the cap until after 24 hours.

- The pressure-sensitive seal liners are suitable for solid medicine like pills, tablets, capsules, and powder, but they are not suggested for liquid. Also, please make sure the bottle mouth is dry when sealing.

- These seals are heat-sensitive and should be stored between 15 to 20° C maximum and at a humidity between 40 and 60%.

Induction Heat Seal:

Usually induction Seal liners are most commonly used as Foil Seal; it is made up of laminated products. The top layer is a paper board, The second layer is wax, and the third is aluminium foil. The bottom layer is a polymer film pressed onto aluminium foil.

How does Induction Heat Seal work?

Induction heat liners are sealed by a heat sealing machine.

The electromagnetic field is emitted through the induction coil of the heat-sensing device, and the eddy current of the coil heats the aluminium foil. The heat causes the wax above the aluminium foil to melt and be absorbed by the pulp board backing. As the wax disappears, the aluminium foil falls off the pulp board.

The aluminium, which is conductive, is heated by eddy currents from the coil. The hot foil melts the thin layer of wax e, which is then absorbed into the pulpboard. When the wax disappears, the foil falls from the pulpboard. On the bottom side of the foil, the polymer that touches the container begins to melt as well. It flows down and hardens again, and finally sticks to the bottle.

Notice:

- The heating time of induction equipment should be precise. If heating over time, the polymer in contact with the bottle mouth melts too quickly, and it is likely that the melted polymer will break without hardening. If heading with a short time, the polymer does not achieve complete melting, which will also lead to incomplete seals.

How to choose the seal?

Before choosing the seal, we need to consider the following :

- What product will be packed?

- What is the storage condition?

- What is the shelf life?

Our suggestions are :

- Pressure-sensitive seals are for solid forms like pill tablets, powders, and capsules; Induction heat seals can be ideally used for liquid.

- For pressure-sensitive seal recommended store condition between 15 to 20° C maximum and at a humidity between 40 and 60%; for induction heat seal, recommended store condition between 15 and 35° C and humidity of between 30 and 80%.

- For pressure-sensitive seals, once they are placed in the caps, they should be used within nine months; for induction heat seals, to ensure their sealing quality, please do not store them for more than 18 months.

- Both seals should be kept from direct sunlight and heat sources.

The reasons lead to unqualified sealing performance.

Pressure-sensitive seal:

- The thread of the cap and bottle are not matching, which will cause the seal not to touch the bottle’s mouth because of the uneven pressure when screwing the caps.

- The pressure seal is too thinner.

- The pressure seal is placed in the right place of the cap.

- The bottle mouth has an uneven surface.

Induction Heat Seal :

- Heating time is too long or short.

- The wax is not melted entirely, and the aluminium foil still sticks to the wax.

- The bottle mouth surfaces, not even.

How to check the sealing performance?

Take some bottles as samples, put glass balls inside each bottle and screw the cap tightly. (For induction heat seal, use the heat machine to seal ) .Please place them in the container with the air extraction device, soak them in water, and vacuum it to the vacuum degree of 27 kPa for 2 minutes, there should be no water going inside the bottle, or no bubbles will occur.

The importance of qualified sealing :

- The air and moisture will go inside the bottle and may react with medicine and cause Drug metamorphic if the sealing is unqualified.

- For the liquid form, if the sealing is not good, the liquid may spill out during transportation.

- If the sealing is not good, it may cause tampering risk.