Plastic and glass material are the most commonly used materials in drug packaging. Plastic bottles are widely used in tablets, capsules, and syrups. Glass is mainly used in oral liquids. Both materials have their advantages and disadvantages. So let’s start to see how to choose the suitable material for your products.

Plastic and Glass are Non-Renewable Resources

Plastic and Glass are made from non-renewable materials.

Plastics are polymers made from oil and natural gas.

And for Glass, the main component is silica or sand. However, not all sand can be turned into Glass; only the sand of the seabed and riverbed can be processed into Glass. So glass sand is the second biggest consume resource. 1 ton of finished glass containers needs about 1.2 tons of raw material.

Plastic Reduces Energy Cost

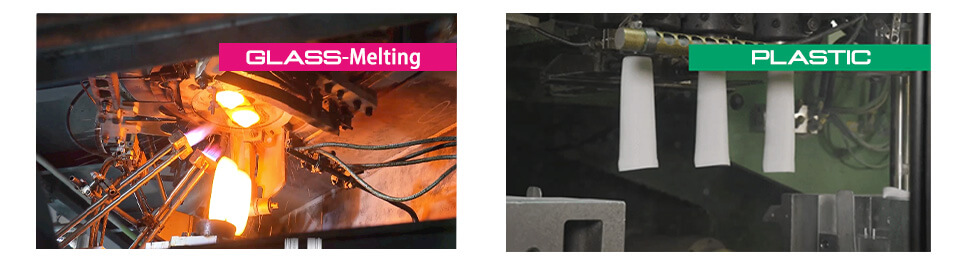

Producing glass containers requires sand, soda ash, and limestone to be melted into a liquid at a temperature of 1500 ° C. And then they cool and are produced into different shapes and sizes containers.

We can see that melting Glass requires a lot of fossil fuels, such as coal, natural gas, etc., which indirectly increases production costs.

However, melting plastic takes a very low temperature, about 170°C, and needs electric heating, so production energy costs are meager.

Plastic Lower Shipping Cost

We all know that Glass is heavier than plastic. Glass has a density of 2.6 g/cm3 compared to HDPE plastic with a density of 0.9 g/cm3 . We take a glass jar and a plastic jar with the same capacity as an example; the weight of a glass jar is 6-8 times that of a plastic jar. Another feature of Glass is that it is fragile. Both glass jars and plastic jars go through different stages in the supply chain, from the container manufacturer shipped to pharmaceutical companies to filling workshops to the warehouse to different distributors to consumers. Considering its heavy weight and fragile, careful handling is required during the transportation of Glass. Meanwhile, if breakage occurs during the shipping process, especially during the shipping of finished products to consumers, it will cause market complaints and increase the overall production cost.

From this, we can see that plastic containers are more safety during shipping.

Plastic Lower the use-cost

When the glass containers are filled in the pharmaceutical company, they should be washed and sterilized first. This process needs the pharmaceutical factory to have enough space to set the facilities for washing and sterilization.

Also, it takes time and labor to finish this stage. The most important is that during the washing glass process, it will cause a loud noise, harming the operators.

For the plastic containers, there is no need to wash them without noise, and they are more friendly to operators.

So, Glass or plastic, which is better?

The most important thing when choosing Glass or plastic is to ensure the drug’s safety inside. Glass or plastic should not affect the drug’s efficiency. Therefore, considering the above-listed factors, plastic packaging will be your top choice if both Glass and plastic are suitable for your product.