1. What are effervescent tablet packaging?

Effervescent tablet packaging is specifically designed to protect effervescent tablets from moisture, light, and air, all of which can degrade the product and reduce its effectiveness. Effervescent tablets typically contain an active ingredient along with an acid and a base, which react when they come into contact with water, leading to the effervescent effect. Due to this reactive nature, such tablets require special packaging considerations. Here are some commonly used packaging solutions for effervescent tablets:

Plastic Tubes

- Material: Often made from high-density polyethylene (HDPE) or polypropylene (PP).

- Features: Air-tight, moisture-resistant, and often equipped with a desiccant cap.

- Use: Ideal for home use and long-term storage.

Aluminum Tubes

- Material: Made from aluminum which offers excellent protection against moisture and light.

- Features: Often come with a membrane seal under the cap for added protection.

- Use: Commonly used in pharmaceutical applications.

Strip Packaging

- Material: Typically a combination of aluminum and plastic or paper.

- Features: Individual sections for each tablet, which are torn or popped open.

- Use: Convenient for on-the-go scenarios but not ideal for long-term storage.

Blister Packs

- Material: Often use PVC or PET plastic along with aluminum foil backing.

- Features: Each tablet is individually sealed, offering good protection.

- Use: Common in pharmaceutical and over-the-counter products for consumer convenience.

Glass Jars

- Material: Made from glass which is excellent at blocking moisture but can be heavy and breakable.

- Features: Often come with air-tight lids and may include a layer of protective material like cotton.

- Use: Less common due to fragility but used for some high-end or specialty products.

Sachet Packs

- Material: Generally made from multi-layer materials including aluminum foil, PE, and sometimes paper.

- Features: Usually contains a single tablet, sealed to keep out moisture.

- Use: Ideal for sample distribution, travel packs, or single-use scenarios.

Pouches

- Material: Often made from laminated materials that include layers of aluminum and plastic.

- Features: Zip-lock or heat-sealed tops make them resealable.

- Use: Typically used for bulk packaging or for institutional use.

These Have the Special Features

- Desiccants: To absorb any moisture, some packages include a desiccant pod or sachet.

- Child-Resistant Caps: For safety reasons, many packaging options come with child-resistant features.

- Information Labels: Important information such as usage directions, ingredients, and expiry dates are usually printed on the package or included as a leaflet.

Understanding the features and uses of each type of packaging can help you make an informed choice, whether you’re a manufacturer looking for the best way to package your product or a consumer seeking to store your effervescent tablets effectively.Let’s delve into the details of plastic effervescent tube packaging.

2. How is the structure of a Plastic Effervescent Tablet Tubes designed?

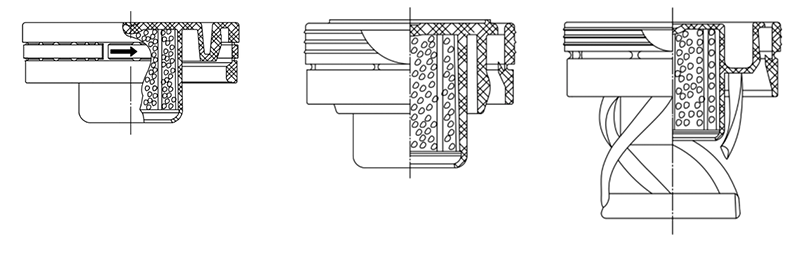

An effervescent tube comprises a plastic tube and a desiccant cap. The desiccant cap contains a desiccant canister, along with a spiral spring.

3. What is the material of the plastic effervescent tube with desiccant cap?

The primary materials used for effervescent tube packaging are polypropylene (PP) and polyethylene (PE).

The tube is made of polypropylene, which is a semi-crystalline thermoplastic. It exhibits high impact resistance, strong mechanical properties, and resistance to various organic solvents and acid-base corrosion. Its appearance is similar to polyethylene but it’s lighter, more transparent, odorless, non-toxic, and has excellent moisture resistance. It can prevent odors from permeating and has high heat resistance, remaining undamaged even after being sterilized in steam at 135°C for 100 hours.

The cap is made of polyethylene. Polyethylene is non-toxic, hygienic, and cost-effective. It boasts good flexibility, and its transparency varies with molecular weight. It has excellent moisture resistance, is easy to process and shape, and possesses great heat-sealing and thermal bonding properties. Additionally, it demonstrates strong cold resistance.

4. What are the characteristics of the plastic effervescent tablet packaging?

The characteristics of the effervescent tube are mainly manifested in the desiccant cap:

- A tamper-evident band is set on the desiccant cap, and a bottle buckle is placed at the neck of the bottle. When the cap is closed, the tamper-evident band gets caught by the bottle buckle. Upon opening, the tamper-evident band automatically detaches, serving as an anti-tampering measure.

- A spiral spring is incorporated into the cap to secure the medication. This prevents the drugs from breaking due to jostling during transportation.

- A small canister is integrated into the cap of the effervescent tube, containing a desiccant. The separation of the desiccant and the medication ensures the safety of the drugs and prevents them from getting damp, thereby preserving the quality of the medication.

5. Applications of plastic effervescent tablet tube?

Plastic effervescent tubes find extensive applications in the pharmaceutical and healthcare industries, primarily for storing and safeguarding various types of effervescent tablets. These tablets may encompass medications, vitamins, mineral supplements, and more. Here are some key applications:

Medical Applications

- Antipyretics and Analgesics: Such as effervescent aspirin or other antipyretic and analgesic medications.

- Antacids and Gastric Medications: Effervescent tablets used to treat conditions like excess stomach acid or indigestion.

- Anti-Inflammatories: Used in oral or other inflammatory conditions.

- Antibiotics and Disinfectants: Especially for oral or skin disinfection purposes.

- Respiratory Medications: Effervescent tablets used to relieve cough or nasal congestion.

Healthcare Applications

- Vitamin Supplements: Common examples include effervescent vitamin C, vitamin D, and B-complex vitamins.

- Minerals and Electrolytes: Effervescent tablets containing minerals like calcium, magnesium, and potassium, commonly used for electrolyte replenishment during exercise or in hot environments.

- Energy Supplements: Typically containing caffeine and other energizing ingredients.

- Antioxidants: Effervescent tablets rich in antioxidants, such as those containing tea polyphenols or other plant extracts.

6. Common Specifications of Effervescent Tubes

7. What is the function of the sealing cap on the effervescent tube?

The sealing cap of effervescent tubes serves multiple vital functions, primarily aimed at preserving the effectiveness and stability of effervescent tablets. This specially designed cap provides an airtight environment, blocking the entry of air and moisture, thereby safeguarding the effervescent tablets from dampness and oxidation. Some sealing caps even feature embedded desiccants or silica gel packets to absorb any residual moisture within the tube. Additionally, many of these caps are designed to be child-resistant, enhancing the safety of product usage.Such sealing caps not only extend the shelf life of effervescent tablets but also offer convenience and a secure user experience.

8. Types of Closure for Effervescent Tubes?

Our product portfolio encompasses various crimp-sealed closures with integrated desiccants, with or without tamper-evident features, and the option of having a spiral spring or not.

9. What is the purpose of the spiral in the closure of effervescent tubes?

The internal spiral structure also aids in securing and supporting the effervescent tablets, preventing them from shifting or breaking during transportation or storage.

10. What are the characteristics of high-quality effervescent tubes with desiccant cap?

- Can be opened with one hand.

- Suitable for the elderly and individuals with limited mobility.

- Demonstrates excellent processing capabilities on all common filling systems and production lines.

- Compliant with US FDA and EU regulations for pharmaceutical applications, and US Pharmacopeia <670> for desiccant stoppers.

- The sealing cap can be repeatedly opened and closed.

- The sealing cap fits snugly with the container body.

11. How to Choose Tubes for effervescent tablets?

Effervescent tablet tubes are relatively specialized packaging internationally. They possess distinct professional characteristics, with the overall sealing cooperation between the bottle and cap being extremely crucial for safeguarding the effervescent tablets from moisture. Choosing qualified packaging is of paramount importance for effervescent tablet manufacturers. Apart from the crucial sealing performance, there are several other aspects to consider when it comes to effervescent tablet tubes:

- Appearance: Uniform color, no damage, no oil stains, proper coordination.

- Desiccant Moisture Content: Below 4.8%.

- Drop Resistance: Desiccant must not scatter.

- Cardboard: Moisture content below 6%, no fluorescence reaction, heavy metals below 5 parts per million.

- Dissolution: No heavy metals, easily oxidizable substances, non-volatile materials.

- Microorganisms: Bacteria less than 1000, molds and yeast less than 100, no detection of Escherichia coli.

- Abnormal Toxicity: Must not be detected.

12. How are Effervescent Tubes Decorated?

HD offset printing

- Capable of high-volume printing.

- Fast printing speed.

- Available in multiple colors for realistic displays.

In-mold Label

- Photorealistic printing for more attention and value

- Different surface structures and peel-off labels

- Price-optimized CMYK printing with up to 8 colors and metallic effects

- Good legibility with small font size, thus more information on the same area

13. Is the color of effervescent packaging customizable?

Both the tube and the closure are available in various colors, providing an appealing packaging choice that enhances your brand value.

14. How to Choose Effervescent Tablet Tube Manufacturer?

- Quality Certifications

Look for manufacturers who have obtained relevant certifications such as ISO, FDA compliance, or GMP (Good Manufacturing Practices) for pharmaceutical packaging. - Experience and Expertise

Manufacturers with years of experience are generally more reliable and capable of producing high-quality products.

Ask for case studies or references to understand their expertise better. - Material Quality

Ensure that the manufacturer uses high-quality materials that are suitable for pharmaceutical or healthcare applications, such as food-grade or medical-grade plastics. - Customization Options

Some manufacturers offer customization options like tube sizes, colors, and cap designs. Choose one that can cater to your specific needs. - Production Capacity

Make sure the manufacturer has the production capacity to meet your quantity requirements and delivery timelines. - Cost-Effectiveness

While cost is an essential factor, it shouldn’t compromise the quality. Get quotes from multiple manufacturers and compare them not just based on price but also the value they offer. - Quality Control

Ask about the manufacturer’s quality control processes. Better yet, visit the production facility if possible to inspect their operations first-hand. - Sample Testing

Always request samples and conduct your tests to check the quality, durability, and suitability of the tubes for your effervescent tablets. - Payment and Contract Terms

Review payment terms, minimum order quantities, lead times, and warranties. Make sure all terms are clear and agreed upon in a formal contract. - Reviews and Reputation

Check online reviews or seek recommendations from industry contacts to gauge the manufacturer’s reputation.