When selecting plastic pharmaceutical packaging, it’s crucial to consider a variety of factors to ensure safety, efficacy, and compliance with industry standards.So By asking some questions, companies can select the most appropriate packaging that meets their product requirements, aligns with brand identity, and ensures regulatory compliance, ultimately saving time and resources while enhancing product safety and effectiveness.

Compatibility and Safety

What is the compatibility of the packaging material with the drug formulation?

Assess the potential for chemical interactions, absorption, adsorption, and leaching that could affect the drug’s stability and efficacy.

Does the packaging protect against environmental factors?

Consider whether the packaging provides adequate protection against light, moisture, and temperature variations, which can degrade sensitive formulations.

Regulatory Compliance

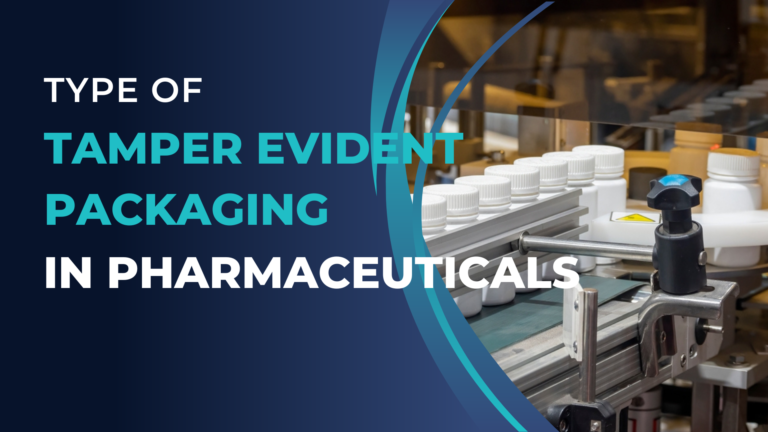

Does the packaging meet regulatory standards?

Ensure that the packaging complies with relevant safety and legal requirements specific to pharmaceuticals, including tamper-evident features and child-resistant designs if necessary.

What certifications does the packaging supplier hold?

Verify that the supplier adheres to industry standards and regulations, which can include ISO certifications or compliance with Good Manufacturing Practices (GMP) relevant to pharmaceuticals.

Material Properties

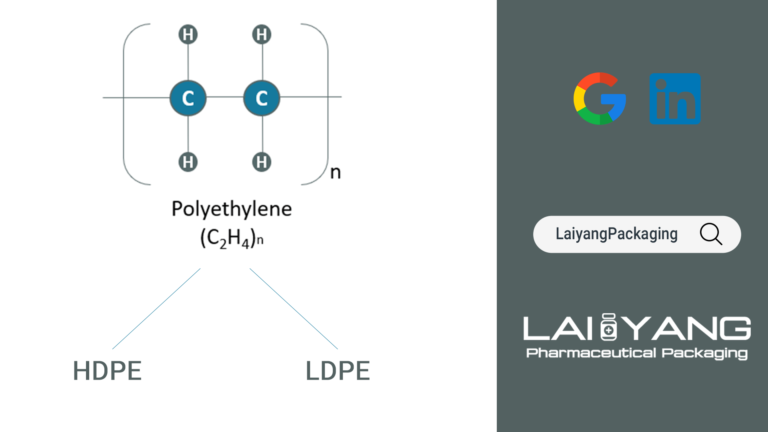

What type of plastic is being used?

Different plastics (e.g., HDPE, LDPE, PET) have varying properties. Evaluate which type best suits the specific needs of the pharmaceutical product, including durability, barrier properties, and recyclability.(Plastic PE /PP/PET | Which is Better for Drugs ?) (Plastic Resin Properties Comparison of HDPE LDPE PET PP)

Is the packaging material sustainable?

Consider the environmental impact of the packaging. Look for options that utilize recycled materials or are designed for recyclability to meet sustainability goals.

Cost and Efficiency

What is the cost-effectiveness of the packaging?

Analyze the balance between cost and quality. While affordability is important, compromising on quality can lead to product integrity issues.

How does the packaging affect logistics and transportation?

Evaluate the weight, durability, and protective qualities of the packaging to minimize damage during transit and handling, which can affect overall costs.

User Considerations

Is the packaging user-friendly?

Consider the end-user’s needs, especially for populations such as the elderly or those with limited dexterity. Packaging should be easy to open while maintaining safety features.

What are the must-have features for the packaging?

Identify essential features such as hermetic seals, child-resistance, or active packaging technologies that can extend shelf life or maintain product integrity.

For the Reader

By addressing these questions, pharmaceutical companies can make informed decisions that enhance product safety, compliance, and user satisfaction while optimizing cost and sustainability.Our sales team has undergone systematic training and education. When they talk to customers, their role as a packaging consultant can answer any questions about packaging.