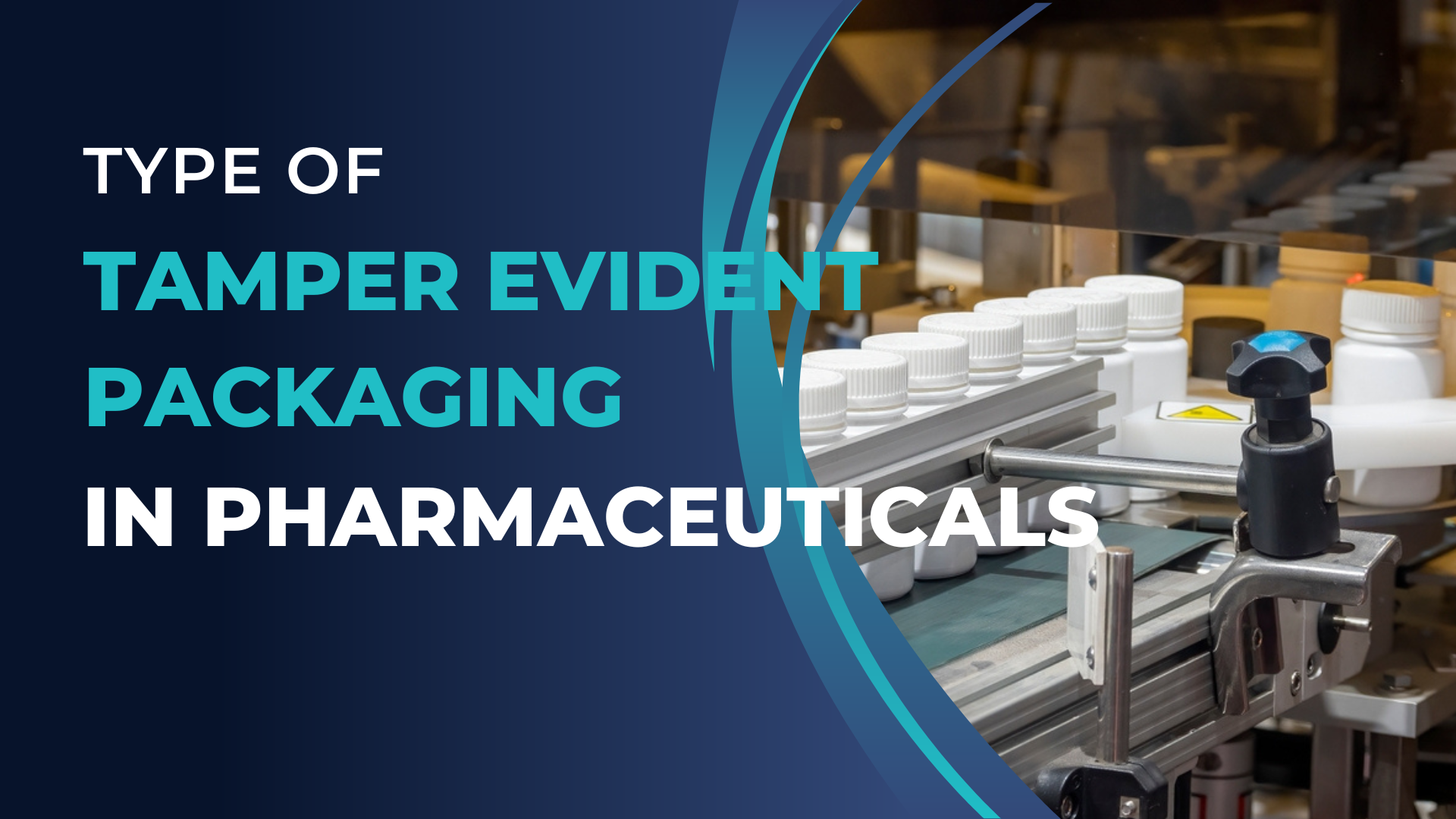

Tamper-evident packaging is essential in the pharmaceutical industry, ensuring the safety and integrity of products by providing clear indicators of unauthorized access. Consumers want to be sure that the items they select are brand new and untainted.When consumers see tamper-evident packaging, it enhances their confidence in the safety and integrity of the product. This trust is crucial for maintaining brand reputation and consumer loyalty in the pharmaceutical market. Then for drugs, tamper-proof needs more attention.

What is Tamper Evident Packaging?

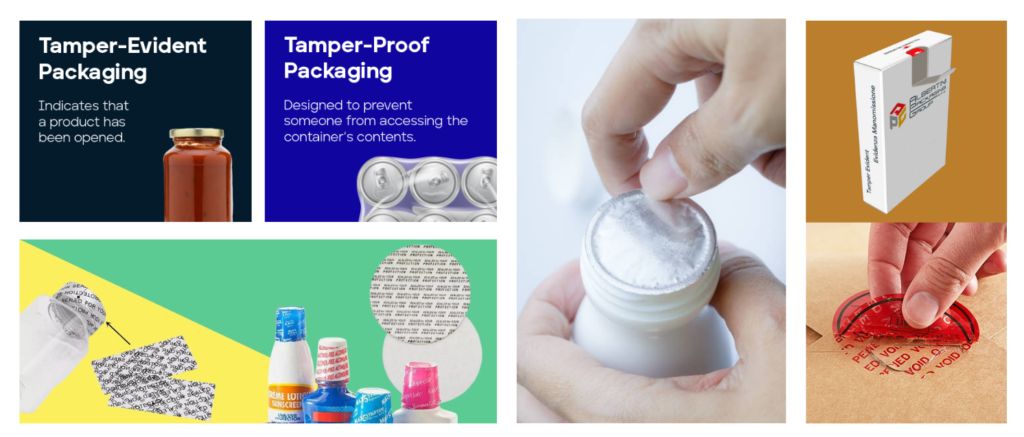

Tamper evident packaging (TEP) is designed to provide clear evidence of unauthorized access or tampering with a product. This type of packaging is crucial across various industries, particularly in pharmaceuticals and food, where safety and integrity are paramount.

Definition and Functionality

Tamper evident packaging incorporates features that alert consumers if a product has been compromised. When tampering occurs, these packaging methods leave visible signs, such as broken seals or damaged materials, indicating that the product may not be safe to use. The U.S. Food and Drug Administration (FDA) defines it as having indicators or barriers that, if breached or missing, provide reasonable evidence to consumers that tampering has occurred.

Importance of Tamper Evident Packaging

Consumer Safety: TEP enhances consumer trust by ensuring that products have not been tampered with, thereby safeguarding health and safety.

Regulatory Compliance: Many industries, especially pharmaceuticals, are required by law to implement tamper-evident features to protect consumers.

Brand Protection: TEP helps maintain brand integrity by deterring counterfeiting and tampering, which can damage a brand’s reputation.

Supply Chain Security: By providing visible evidence of tampering, TEP helps protect products throughout the supply chain, ensuring they reach consumers in a safe condition.

Examples of Tamper Evident Pharmaceutical Packaging

Tamper-proof is widely used in pharmaceutical packaging, whether it is oral solid, oral liquid, capsule and powder had been using it.Some common types of tamper-evident packaging used for pharmaceuticals include:

Tamper Evident Labels Pharmaceutical Packaging

Void Labels: These labels display a “VOID” message when removed, indicating that tampering has occurred. They can be customized with logos or specific messages for branding purposes.

Destructible Labels: Made from a fragile material, these labels break into pieces when someone attempts to remove them. This ensures that any tampering attempt is immediately visible.

Total Transfer Labels: These labels reveal hidden messages or patterns when tampered with, providing a clear indication that the product has been opened or altered.

Perforated Labels: Designed with perforations, these labels visibly tear along the lines when opened, making it easy to identify tampering.

Tamper Evident Shrink Bands: These are plastic bands that fit around the neck of bottles or jars. They must be torn to access the product, serving as a visible indicator of tampering when damaged.

Tamper Evident Carton Seals: These seals are applied to folding cartons and reveal evidence of tampering through void messages or damaged label material when removed.

Tamper Evident Seals for Pharmaceuticals

tamper evident cap for eye dropper bottle

child resistant cap with tamper evident for oral syrup bottle

FDA Tamper Evident Packaging Requirements Pharmaceutical

The FDA has established specific tamper evident packaging requirements for pharmaceutical products, particularly for over-the-counter (OTC) medications. These regulations are designed to enhance consumer safety by ensuring that any tampering with a product is clearly visible. Here are the key requirements outlined by the FDA:

General Requirements

Tamper-Evident Features: Each OTC drug product must be packaged in a tamper-evident package. This means the packaging must have one or more indicators or barriers to entry that, if breached or missing, provide visible evidence to consumers that tampering has occurred.

Distinctive Design: The tamper-evident feature must be distinctive by design, meaning it cannot be easily duplicated using commonly available materials or processes. This includes using unique patterns, logos, or trademarks that are not readily available to the public.

Packaging Types: Acceptable forms of tamper-evident packaging include:

- Blister packs: Where each dosage unit is individually sealed.

- Shrink bands: Plastic bands that fit around the neck of bottles.

- Induction seals: Foil seals that create an audible pop when first opened.

- Film wrappers: Transparent films that must be cut or torn to remove the product.

Labeling Requirements: The packaging must include a prominent statement that identifies the tamper-evident features used. This labeling must remain intact and legible even if the tamper-evident feature is breached. For example, a label might state, “For your protection, this bottle has an imprinted seal around the neck”.

Capsule Requirements: For two-piece hard gelatin capsules, there must be at least one tamper-evident feature, and it must be sealed using an acceptable tamper-evident technology.

Compliance and Enforcement: Failure to comply with these requirements can result in the product being deemed adulterated or misbranded under the Federal Food, Drug, and Cosmetic Act, leading to regulatory actions against the manufacturer.

These requirements are part of the FDA’s broader efforts to ensure the safety and integrity of pharmaceutical products, helping to protect consumers from potential harm due to tampering.

For the Reader

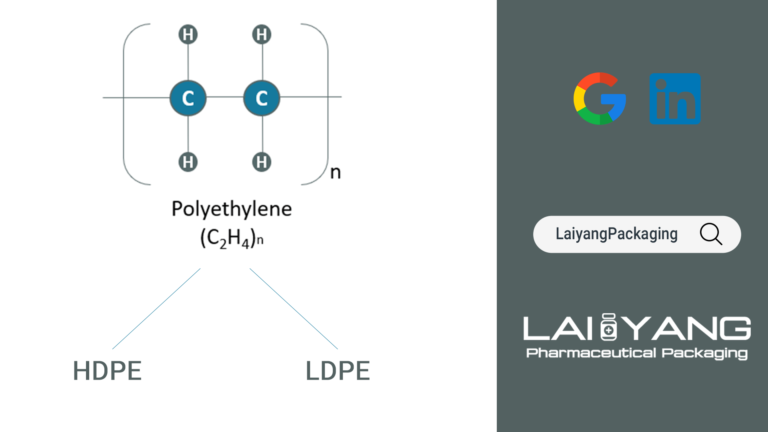

Do you have a new product that needs packaging? Do you want to differentiate your brand with new packaging, or do you want to discuss resin options for an existing bottle? Work with us and you have access to over 20 years of manufacturing expertise. Our knowledgeable team can help you determine which type of resin and which bottle will work best for your product.