What are Oral Syringes

Oral syringes are specialized measuring devices designed for the precise administration of liquid medications, particularly for oral use. They play a crucial role in healthcare settings by ensuring that medications are delivered safely and accurately, especially for vulnerable

populations such as children and patients with specific medical needs. The use of oral syringes is critical in preventing serious medication errors. The Institute for Safe Medication Practices (ISMP) has consistently advocated for the exclusive use of oral syringes for oral and enteral medications to enhance patient safety.

Key Features for Oral Syringe Manufacturers

Design Specifications

Needle is Unaccommodated: Oral syringes cannot accommodate a needle attachment to prevent accidental connections to intravenous (IV) systems, thereby reducing the risk of wrong-route medication errors.

Graduated Scale: Clear calibration markings in milliliters must be imprinted on the barrel for accurate dosing. Different sizes (e.g., 1 mL, 5 mL, 10 mL) should be available to accommodate various medication volumes.

Material Composition

Biocompatibility: Materials used (e.g., polypropylene for barrels and synthetic rubber for stoppers) must comply with ISO 10993-1 standards for biocompatibility.

Latex-Free Options: Syringes should be latex-free to prevent allergic reactions in sensitive individuals.

Manufacturing Standards

ISO Certification: Compliance with ISO standards such as ISO 9001 and ISO 13485 is essential, ensuring quality management systems are in place for medical devices.

Good Manufacturing Practices (GMP): Manufacturers must adhere to GMP guidelines throughout the production process, including material inspection, in-process inspections, and final product testing.

Safety Features

Color Coding: Use distinct colors (e.g., purple or amber) that differentiate oral syringes from parenteral syringes to minimize confusion and potential errors during medication administration.

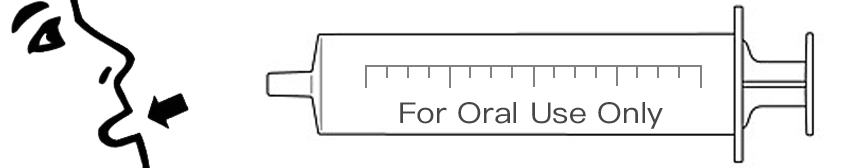

Labeling: Clear labeling indicating “Oral Use Only” should be present on the syringe to reinforce proper usage.

Usability Considerations

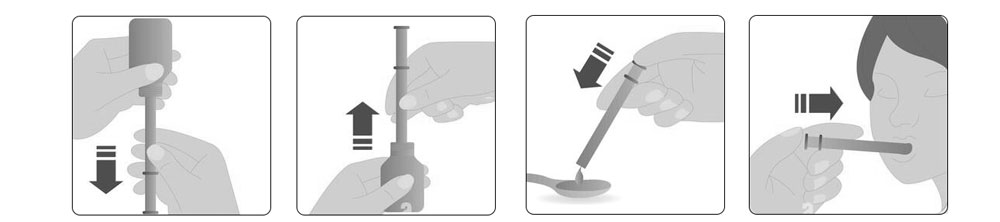

User-Friendly Design: The syringe should be designed for easy handling and filling, potentially incorporating features like a patented wiper design to ensure a complete seal without small rubber parts that could pose choking hazards.

Visual Inspection: Implement a system for 100% visual inspection of calibration lines to ensure accuracy before packaging.

Regulatory Compliance

FDA Regulations: Ensure that the product meets all relevant FDA regulations for Packaging Materials, including registration and labeling requirements.

Clinical Testing: Conduct clinical evaluations as necessary to demonstrate safety and efficacy in intended use scenarios.

The Main Certifications For Oral Syringe Manufacturer

An oral syringe manufacturer should have several key certifications and adhere to important standards to ensure the safety and quality of their products.

- ISO 9001: This certification ensures that the manufacturer has a quality management system in place for the design and manufacturing of medical devices.

- ISO 13485: This standard specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements.

- CE marking indicates that a product meets the essential requirements of the relevant European health, safety and environmental protection legislation. It is a mandatory conformity marking for certain product groups, including medical devices.

What Are The Key Safety Features Of Oral Syringes

- Needle unavailable

Oral syringes typically cannot accommodate a needle attachment, which prevents accidental connections to intravenous (IV) lines and other medical devices. This design is crucial in avoiding the serious risk of administering oral medications intravenously, which can lead to severe complications or even death. - Color-Coding

Many oral syringes are color-coded to differentiate them from parenteral syringes and other types of syringes. This visual cue helps healthcare providers quickly identify the syringe intended for oral use, reducing the likelihood of mix-ups. - Clear Calibration Markings

Oral syringes are marked with clear and easy-to-read calibration lines that allow for accurate measurement of liquid medications. This feature is essential for ensuring that patients receive the correct dosage, particularly in pediatric care where precise dosing is critical. - Oral Adapters

Some oral syringes come with oral adapters that facilitate easier administration of medications, especially for patients who may have difficulty swallowing. These adapters help ensure that the medication can be delivered safely and effectively. - Patient Safety Features

Certain manufacturers incorporate designs that minimize contamination risks, such as a patented wiper design that eliminates small rubber parts that could pose choking hazards. This attention to detail enhances overall safety during medication administration. - Auxiliary Labels and Warnings

Oral syringes often include auxiliary labels stating “For Oral Use Only,” which reinforces proper usage and serves as a reminder to healthcare providers to avoid using them for injections.

Customization Options for Oral Syringe Manufactures

- Custom Imprints: Manufacturers can provide oral syringes with custom imprints, including logos and specific markings that may include the medication name or dosage instructions. This enhances brand visibility and ensures clarity in dosing.

- Resin Colors: Manufacturers often offer a range of colors for syringe components, such as plunger and barrel colors. Common options include white for stock items, with made-to-order colors like yellow, orange, red, purple, blue, light green, dark green, and turquoise available.

Barrel Colors: Clear and amber barrels are available, with amber options being particularly useful for light-sensitive medications. - Unique Calibration Lines: Custom calibration markings can be designed to meet specific dosing requirements or preferences, improving usability for healthcare professionals.

- Syringe Sizes and Capacities: Manufacturers provide a range of sizes from 0.5 mL to 20 mL to accommodate various medication volumes. Custom sizes can also be produced based on client specifications.

- Tip Modifications: Tips can be modified for compatibility with various adapters and fittings, enhancing the versatility of the syringes in different applications.

- Packaging Options: Custom wrapping options are available, including individual wrapping in bags or pouches and shrink-wrapping. This ensures hygienic delivery and storage of the syringes.

- Regulatory Compliance Options: Custom syringes can be designed to meet specific regulatory requirements, such as CE marking for the European market, ensuring compliance with local regulations.

- Accessories: Manufacturers may also offer custom accessories such as press-in bottle adapters that enhance dosing accuracy when filling oral syringes.

Different Types for Oral Syringes

Oral Syringes for Child

√ Capacity: 0.5ml, 1.25ml, 1.5ml, 3ml, 5ml, 10ml

√ Features: Tip and Non-Tip Options

√ Suitable for pediatric medicines, suspensions, or drinkable, THC, CBD Oil solutions

√ Plug DIN28 and DIN18 and sealing cap

√ Can be used upside down with a connector

√ Strong legibility and easy administration

√ Long lasting and easily recyclable

√ Individually wrapped on request

√ Very hygienic when used with a Press-In Bottle Adaptor (PIBA)

Oral Syringes for Pets

√ Precise design with good sealing and no leakage

√ Barrel and plunger fit well, easy to use

√ The color of all parts can be customized based on your brand image

√ The scale on the plunger can be customized per your request

√ Both production and package process in clean room

√ Offering high quality hot transfer printing service on the barrel

√ Different assemble ways for your choice to ensure convenient filling method

√ Sterilization available