In the pharmaceutical and health care industries, PET bottles are widely used due to their unique properties. They not only effectively protect products but also enhance brand image. Therefore, ensuring the quality of PET bottles is crucial for product safety and maintaining brand reputation.

The Importance and Use of PET Bottles

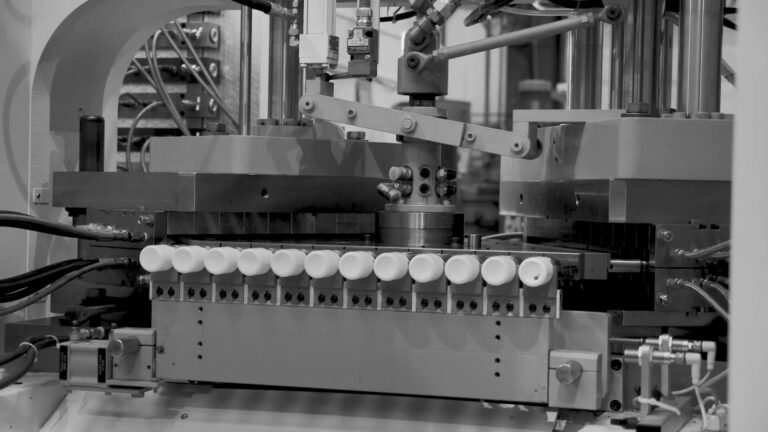

PET bottles are extensively used in pharmaceutical packaging mainly because they are lightweight, durable, and recyclable. The chemical stability of PET material prevents reactions with medications, ensuring drug safety. These properties make PET bottles an ideal choice for pharmaceutical packaging.

The Importance of Checking PET Bottle Quality

High-quality PET bottles can prevent contamination of medicines or damage during transportation. Conversely, substandard packaging can pose significant risks, including product damage and health hazards. Therefore, for pharmaceutical companies, checking the quality of PET bottles is not just about compliance with industry standards but also a responsibility towards consumers.

How to Check the Quality of PET Bottles

- Vacuum Leak Test: This test checks for leaks in bottles after blow molding. The bottle is tested in a vacuum environment; if it collapses upon vacuum release, it indicates a quality issue.

- Top Load Test: This test assesses the compressive strength of PET bottles when subjected to top pressure. It helps identify weaknesses and imperfections by simulating conditions of stacking, handling, and transportation.

- Appearance Inspection: Examine the bottle’s surface for smoothness and absence of noticeable scratches or damage. A good appearance is not only about aesthetics but also a crucial aspect of quality control.

- Bottle Body Inspection: Ensure the upper and lower parts of the bottle align vertically, and the wall thickness is uniform. Uneven wall thickness can lead to instability in performance, affecting safety and practicality.

The Significance of Testing for Procurement, R&D, and Marketing Personnel

- For Procurement Personnel: Comprehensive quality testing helps procurement officers identify the best suppliers, ensuring the bottles purchased meet safety, hygiene, and environmental standards.

- For R&D Personnel: R&D teams use test results to improve and optimize PET bottle design. Top Load Test results, for example, can guide adjustments in bottle shape and wall thickness distribution, enhancing overall strength and pressure resistance.

- For Marketing Personnel: Sales teams can use these test results as selling points, demonstrating the high standards and superior quality of the company’s products. High-quality PET bottles not only enhance market competitiveness but also increase consumer trust and loyalty in the brand.

Conclusion

Ensuring high-quality PET bottles is vital for maintaining product integrity, ensuring user safety, and enhancing brand image. Procurement, R&D, and marketing personnel should all pay attention to the quality inspection of PET bottles, ensuring they meet customer needs and expectations. By implementing stringent quality control measures, we not only guarantee the high quality of our products but also stand out in a competitive market.